Microbial analysis is essential for assuring the safety and quality of our food. The presence of dangerous microbes in food can cause foodborne illnesses and pose serious dangers to public health. As a result, reliable and effective detection, identification, and control of microbiological contamination is critical in the food sector.

This comprehensive post examines the significance of microbiological analysis in food safety, including common contaminants, analysis methods, procedures, the function of HACCP, regulatory standards, problems, and future perspectives. Understanding the significance of microbiological analysis allows us to better safeguard customers and improve food safety processes.

Understanding Microbial Analysis

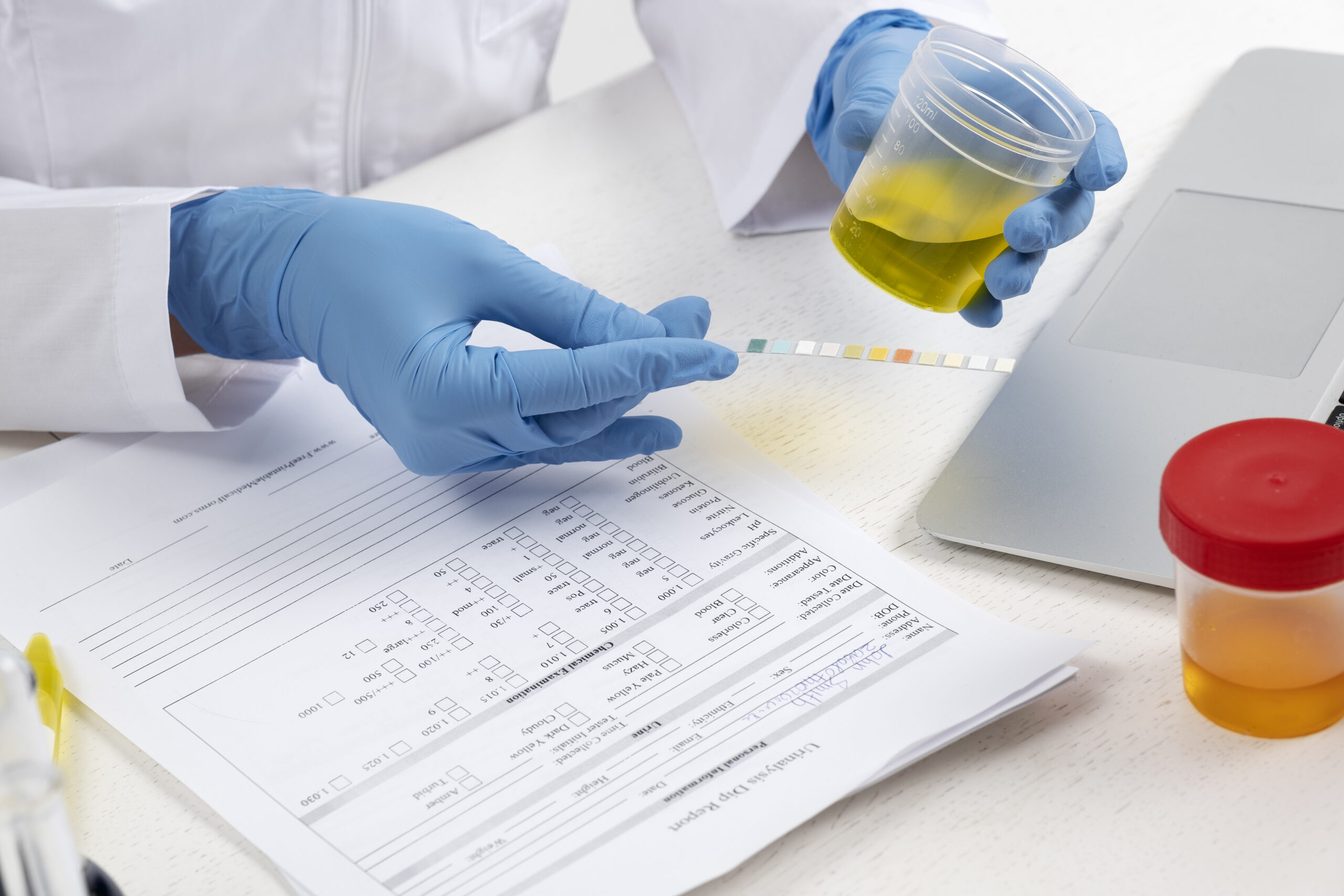

Did you know that hidden dangers are lurking in our food? These dangers come from tiny microorganisms like bacteria, viruses, fungi, and parasites. They can make us sick if we eat contaminated food. Microbial analysis allows scientists to examine these microorganisms and determine which ones are present in our food.

The Role of Microbial Analysis in Food Safety

1. Detecting Pathogens

Some microorganisms, called pathogens, are especially dangerous. They can cause serious illnesses like Salmonella, E. coli, Listeria, and Campylobacter. By using microbial analysis, experts can quickly find out if these pathogens are in our food. This helps prevent outbreaks and keeps us safe.

2. Monitoring Microbial Growth

Microorganisms naturally grow in our food, but not all of them are harmful. Some can even be helpful. However, others can spoil our food or produce toxins that make it unsafe to eat. By regularly checking the levels of microorganisms in our food, producers can make sure it stays fresh and safe to eat for longer.

-

Common Microbial Contaminants in Food

- Bacteria

- Viruses

- Fungi and Molds

3. Ensuring Compliance with Regulatory Standards

Governments and organizations have set rules to make sure our food is safe. Microbial analysis is an important part of these rules. Food manufacturers and processors have to test their products regularly to make sure they meet these standards. This shows that they care about our safety and want to give us good food.

-

Identifying Critical Control Points (CCPs)

Microbial analysis aids in identifying areas in the food production process where control is required to avoid or remove a food safety problem. These points, known as Critical Control Points (CCPs), guarantee that microorganism-related risks are minimized. Microbial analysis allows us to identify important periods and take the required procedures to assure the safety of our food.

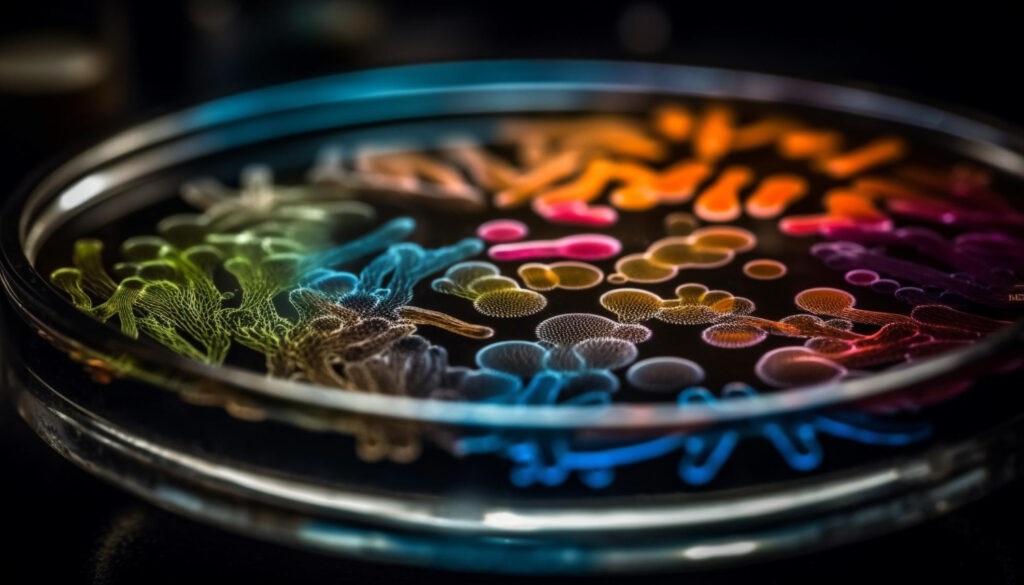

4. Advancing Technology in Microbial Analysis

In recent years, technology has made microbial analysis even better. Automated systems, high-tech sequencing, and special tools have made the process faster and more accurate. This helps experts identify different microorganisms and their characteristics quickly. With these advancements, we can stay ahead of new threats and respond faster to any problems.

5. Regulatory Standards and Guidelines for Microbial Analysis in Food Safety

In the area of food safety, laws and guidelines are just as crucial as seasoning in a good dish. Several international organizations and national/regional entities have established guidelines for microbiological analysis to ensure that things run smoothly.

-

International Organizations and Regulations

International agencies such as the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) have created standards and guidelines to assure food safety from a microbiological standpoint. These guidelines serve as a framework for microbiological investigation and contribute to the development of a global food safety standard.

-

National and Regional Standards

International agencies such as the World Health Organization (WHO) and the Food and Agriculture Organization (FAO) have created standards and guidelines to assure food safety from a microbiological standpoint. These guidelines serve as a framework for microbiological investigation and contribute to the development of a global food safety standard.

Challenges and Future Directions

Even the powerful microbiological analysis has its own set of obstacles and limitations. It’s like attempting to carve a perfectly ripe avocado without bruising it: difficult, but not impossible. New dangerous microorganisms, resistance to medicine, and global food supply chains are ongoing problems. To solve these problems, experts need to work together, invest in research, and share knowledge. This will help us make our food even safer in the future.

-

Sampling Issues and Variability

One of the difficulties in microbiological analysis is sampling. Obtaining a representative sample from a large batch of food can be as challenging as locating a misplaced sock in the dryer. Additionally, variability within the same batch of food can make it hard to accurately assess microbial contamination. Think of it like trying to predict the weather in a tropical rainforest – it can be unpredictable!

-

Detection and Identification Challenges

Microorganisms are like tiny ninjas, stealthily hiding in our food. Identifying and detecting them can be a game of hide-and-seek. Some microorganisms have unique characteristics that make them harder to detect or identify accurately. It’s like trying to determine if that mysterious stain on your shirt is ketchup or something else entirely.

-

Cost and Time Constraints

While microbiological analysis is critical for food safety, it may be costly and time-consuming. Conducting comprehensive examinations can be costly and time-consuming. It’s like going on a shopping spree and attempting to locate the perfect dress on a tight budget and limited time. It requires careful planning and prioritization.

Conclusion

The microbial analysis is like a superhero in the world of food safety. It combines science, technology, and rules to keep us safe. By using microbial analysis, we can find out what’s in our food and make sure it’s safe to eat. As we move forward, let’s stay alert, take action, and keep working towards making our food as safe as possible.

Inadequate sampling strategies are a common error in microbial analysis. Improper sampling can result in biased or incorrect results. Common problems include the use of contaminated equipment, insufficient sample size, inappropriate collecting procedures, and a lack of representative sampling from the target area.

Inadequate sampling strategies are a common error in microbial analysis. Improper sampling can result in biased or incorrect results. Common problems include the use of contaminated equipment, insufficient sample size, inappropriate collecting procedures, and a lack of representative sampling from the target area.